The older generation of raised floors were designed to run air through the floor to cool off the tremendous heat that computers generated. Because of new technology, computers no longer produce the kind of heat they used to–so running air through the floor is no longer necessary. In short, you don’t need all that plenum space.

Low Profile Raised Floor Systems vs Traditional Raised Floors

Low profile raised floor systems are often an overlooked choice because when people think of raised floors they typically think of traditional options that are designed for underfloor air distribution. But if you are looking for cable management and flexibility, low profile raised floor systems are a better choice over traditional raised floor options. There are plenty of reasons why a low profile access floor is likely a better choice if you do not need underfloor air.

Traditional Raised Flooring System

What is a traditional raised access floor?

First of all, these standard raised floors are generally defined as any raised floor 15cm or higher above the subfloor. But they’re usually 30cm or more, with some floors reaching 2m or higher.

The traditional raised floor creates a sealed airspace and is intended for running underfloor air distribution. While they can be used for cable distribution, cable trays and / or conduit is recommended for segregation. They can also accommodate mechanical equipment under the floor. Traditional raised floors are often found these days in data centers and industrial applications.

The key components of the traditional raised access floor are as follows:

Floor Panel: This is the horizontal load-bearing element of the floor. Each panel is a square tile, usually the standard size of 60x60cm. The panels can be made of the following materials: steel pan with concrete-fill, steel pan with woodcore, hollow steel and aluminum; finishes include bare concrete or high-pressure laminate. Panels usually weigh at least 15kg and require specialty labour and tools to install and move.

Pedestal: This is a vertical, adjustable post that supports the floor panels described above. The pedestals are usually bonded to the subfloor with an epoxy resin-based adhesive and with mechanical fixings, if required. Please note that this flooring is affixed to the building structure.

Stringer: This a horizontal piece of hardware that connects to the pedestal head, thus adding additional lateral floor support.

If you require underfloor air distribution or need to accommodate equipment under the floor, then you should consider this type of solution. You’ll have to hire outside contractors or have highly-trained inside personnel to service it. This flooring system doesn’t provide easy access to the wires, cables, and piping under the floor. The individual panels are heavy and require the use of special tools to open up to access the plenum. Also, it’s not advisable to pull too many floor panels at once, as the entire floor can lose stability.

Now, let’s compare with an alternative.

What is a low profile raised floor system?

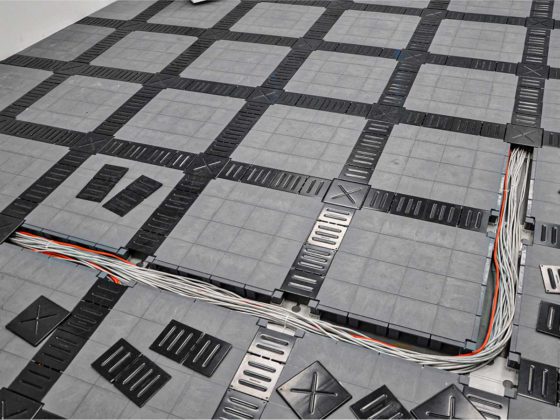

Low profile raised access floors have a height of less than 15cm from the subfloor. The Cabloor Low Profile Cable Management System has a super-low profile with a height of 6cm.

If you’re not running equipment like a huge 20cm chilled water line under your floor and the objective is flexible cable management — not underfloor air — you don’t need a traditional raised access floor.

If you are running electrical conduit and data cables for an office space, a library, a computer room, a retail store, etc., the Cabloor cable management system is the perfect solution for your cable management needs. Cabloor has high cable capacity, more than sufficient for any office or technology building.

No panels. No pedestals. No stringers.

Each unit is made of a polypropylene core component with 64 integrated self-supporting legs which affords unparalleled floor support and stability. The Cabloor system weighs only 10kg per square metre, which is about 4 times lighter than the average traditional raised floor.

And don’t let the “lightweight” throw you. Cabloor exceeds International Building Code requirements for Commercial Office Buildings and several other applications including call centers, libraries, manufacturing centers, museums, emergency operations centers, classrooms etc.

Cabloor components are laid out on a matrix which is held together by gravity. There’s no need for vertical pedestal supports that are affixed to the subfloor. In fact, Cabloor doesn’t attach to the building at all.

Low Profile Raised Flooring System

Following is an explanation of why Cabloor low profile raised floor systems have gained in popularity over traditional raised access flooring.

A side-by-side comparison:

| Standard Raised Access Flooring | Low Profile Raised Floor Systems |

| Requires a specialist to install, organize and service the distribution of cables, vents, wires and equipment. | Simple. Requires no special knowledge or expertise to install or modify at a later date. |

| Extra time and cost needed for grounding and bonding; fire suppression, cable tray and other accessories; custom panel cuts and support at wall and columns.

Installation is a lengthy process. |

Fast. Flooring can be installed at a rate of 80-90 square meters a day per installer. No need for trenching or coring, as the process follows the natural contour of the subfloor. This is 3 times faster than the time required to install a traditional access raised floor and will save you weeks of time on your project. |

| It’s expensive, due to the need for specialists to install and the time lost with the use of this slow, labor-intensive method. | Cost-effective. Costs are lower due to the simple installment method. Project time is reduced, allowing you to get back to business as soon as possible. Saves time and money. |

| Hard to access. Once installation is complete, it becomes challenging to make any further alterations. Any changes must be done by a specialist. The flooring is heavy and needs special tools to lift the floor panels. | Easy access. Changes to the cable or wiring system are simple, easy, and anyone can do it. You can work on one section of the floor without disturbing other areas where employees are working. |

| Less floor-to-ceiling space in the building. | More ceiling-to-floor space in the building. |

| Not reusable. This floor is attached to the building. Should you move, you are unable to move the floor with you. | Reusable. Cabloor is a long-term investment. The flooring isn’t attached to the building, so if you move, the floor can move with you. |